Product Introduction

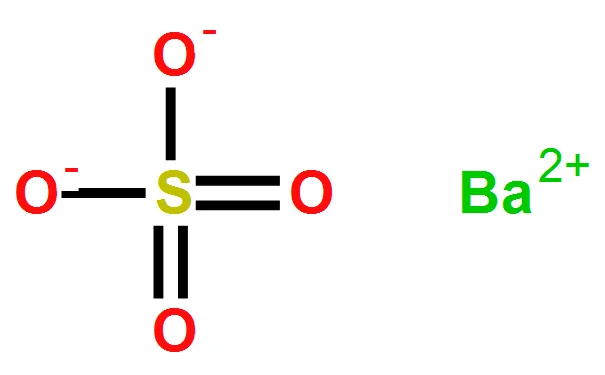

Barium sulfate is also known as barite, chemical formula BaSO4, colorless or white orthorhombic crystal. When heated to 1149 ° C, it becomes a monoclinic crystal, and the refractive index is 1.649. Almost insoluble in water, 0.00022 at 18 ° C, 0.00041 at 100 ° C, slightly soluble in concentrated sulfuric acid; dissolved in alkali metal carbonate solution, becomes barium carbonate; insoluble in other acids and bases. In nature, it exists as a barite mineral. The natural mineral is called barite. Co-heated with carbon (pulverized coal) to 800 ° C, reduced to soluble barium sulfide and carbon monoxide. It has the ability to strongly absorb X-rays, X-rays are not permeable, and can be used medically as an agent for X-ray gastrointestinal tract (barium meal). Barium sulfate is the only non-toxic barium salt. Used in the analysis of reagents, electronics, instrumentation, metallurgy and other industries, as a white pigment, medicinal agent for gastrointestinal X-ray fluoroscopy, copper smelting agent, drilling mud specific gravity increasing agent and white filler for rubber, paper and plastic. It is prepared by reacting sulfuric acid with cerium chloride.

Method 1: The open slope mining method for the residual slope deposit, the majority of the primary ore mining method.

Method 2: Barium chloride-supplemental nitrate method The refined barium chloride is reacted with refined thenardite to form barium sulfate precipitate.

Method 3: The comprehensive utilization method of salt and brine, the reaction of samarium yellow halide with Glauber's salt, followed by acid boiling, water washing, separation and dehydration, and drying to obtain a finished product of barium sulfate.

Method 4: Glauber's salt-black ash method.

Parameters

Physicochemical properties | |

Density | 4.5 |

Melting point | 1580oC |

Boiling point | 330 ° C at 760 mmHg |

Chemical properties | white powder |

Storage conditions Ventilation | low temperature drying, separate storage from aluminum and potassium |

Product Details

Used as raw materials or fillers for paints, inks, plastics, advertising pigments, cosmetics, batteries, rubber products for both fillers and reinforcing agents, as fillers and weighting agents in polyvinyl chloride resin, printing Surface coating agent for paper and copper paper, sizing agent for the textile industry. Glass products are used as clarifying agents to defoam and increase gloss. It can be used as a protective wall material for radiation protection. Also used in ceramics, enamel, spices and pigments.

It is also the raw material for the manufacture of other barium salts - powder coatings, paints, marine primers, ordnance equipment paints, automotive paints, latex paints, interior and exterior architectural coatings, which can improve the light, weather, chemical and electrochemical corrosion resistance of products and products. Decorative effect to enhance the impact strength of the coating. The inorganic industry is used as a raw material for the manufacture of other cerium salts such as cerium hydroxide, cerium carbonate, cerium chloride and the like.

The wood industry produces wood grain printing plates for baseting and modulating printing paints. In organic synthesis, a green filler is produced as a green pigment and a lake. Printing - ink filler, can play the role of anti-aging, anti-exposure, increase adhesion, clear color, bright, and no fading. Filler - tire rubber, insulating rubber, rubber sheet, tape, engineering plastics can enhance the product's anti-aging properties and weather resistance, the product is not easy to age and become brittle, and can significantly improve the surface finish, reduce production costs, as a powder coating The main filler is the main means to adjust the bulk density of the powder to increase the powder rate.

Functional materials - papermaking materials (mainly paste products), flame retardant materials, anti-X-ray materials, battery cathode materials, etc. They all show unique performance and are an indispensable part of related materials.

Other fields - ceramics, glass raw materials, special resin touch materials, precipitated barium sulfate with special particle size distribution and titanium dioxide compound, have synergistic effect on titanium dioxide, and thus reduce the amount of titanium dioxide.