Overview

Quick Details

Classification:

Carbonate

Type:

Reinforcing agent

CAS No.:

471-34-1

Other Names:

Calcium carbonate

MF:

CCaO3

EINECS No.:

207-439-9

Grade Standard:

Industrial Grade

Purity:

98.5%

Appearance:

White power

Application:

Reinforcing agent

Brand Name:

Richest

Supply Ability

Supply Ability:

5 Ton/Tons per Month

Packaging & Delivery

Packaging Details

25kg/bag or customized packing

Port

Shanghai port or any other major port of China

Picture Example:

Product Description

CAS No.: 471-34-1

MF: CCaO3

EINECS No.: 207-439-9

Calcium carbonate, also known as limestone, stone powder, is a common chemical on the earth, belonging to inorganic salt minerals, alkaline, insoluble in water, soluble in acid, naturally existing in graupel, calcite, chalk, limestone, marble, limestone and other rocks, insoluble calcium carbonate and dissolved carbon dioxide water in lime strata can be converted into calcium bicarbonate, and water soluble with calcium bicarbonate can also precipitate calcium carbonate. This is the reason for the formation of caverns.

Calcium is necessary to maintain the normal permeability of nerve, muscle, skeletal system, cell membrane and capillaries. Calcium carbonate is the main component of animal bone or shell. Calcium carbonate used in medicinal and edible addition is prepared by calcite. Due to the effect of calcium supplementation after purification, sterilization, filtration and purification, penicillin, streptomycin and oxytetracycline need to be widely used in the preparation of penicillin, streptomycin and oxytetracycline. As an additive in food to ensure the necessary calcium intake, such as gum, chocolate and Wa, giant energy calcium, jelly happy Lang and other drinks to meet the needs of the human body for calcium.

According to the different production methods, calcium carbonate can be divided into light calcium carbonate, heavy calcium carbonate and active calcium carbonate. The preparation method of light calcium carbonate (abbreviated as light calcium) is that limestone and other raw materials are calcined to form lime (mainly composed of calcium oxide) and carbon dioxide, and then the lime is digested with water to form lime milk (mainly calcium hydroxide), and then carbon dioxide carbonation lime milk is added to form calcium carbonate precipitation. Finally, it is prepared by dehydration, drying and crushing. Or calcium carbonate precipitation by double decomposition of sodium carbonate and calcium chloride, and then prepared by dehydration, drying and crushing, mainly used as fillers in rubber, plastics, papermaking, paint, ink and other industries, as well as in dental powder, toothpaste, cosmetics and other daily chemical products, as well as organic synthesis, metallurgy, glass and asbestos production.

The preparation method of heavy calcium carbonate is made by directly crushing natural calcite, limestone, chalk, shell and so on by mechanical method. It is an excellent filling agent and performance improver, which is widely used in plastics, rubber, papermaking, coating, feed, medicine, daily chemical industry, glass, ceramics and so on. The preparation method of active calcium carbonate (active calcium) is prepared by surface modification of light calcium or heavy calcium by surface modifier. the modified calcium carbonate powder has a special coating structure on the surface, which can significantly improve the dispersion and affinity in polyolefine and other polymer matrices, and can interact with the polymer matrix to improve the interface between the modified calcium carbonate powder and the polymer matrix.

Item | Index |

Melting Point | 825 °C |

Form | White-beige to slightly beige-gray powder or crystals |

Density | 2.93 g/mL at 25 °C(lit.) |

Storage | Store at RT. |

Solubility | 5 M HCl: 0.1 M at 20 °C, clear, colorless |

Water Solubility | Insoluble |

Stability | Stable. Incompatible with acids, fluorine, ammonium salts, alum. |

Explosive Limit | 1.6583 |

It is the filling material of rubber, which can make the rubber bright in color, high in extension, high in tensile strength and good in wear resistance. Also used as artificial leather, wire, polyvinyl chloride, paint, ink and paper and other industrial fillers. When used in the production of micro-l rubber, it can be foamed evenly.

It is also widely used in rubber, adhesive and sealant as filler and reinforcing agent.

Used in rubber, can effectively improve the compressive strength, wear resistance and extrusion strength of rubber products; used in plastic products, make the surface smooth, replace some pvc resin dosage; used in papermaking, can improve the gloss, whiteness and imtransparency of coated paper, improve the printability of paper, widely used in extinction paper, carbon-free copy paper, paper quantitative coating paper, white cardboard and so on.

Our Company

Our Factory

Our Team

Exhibition

Packing&Shipping

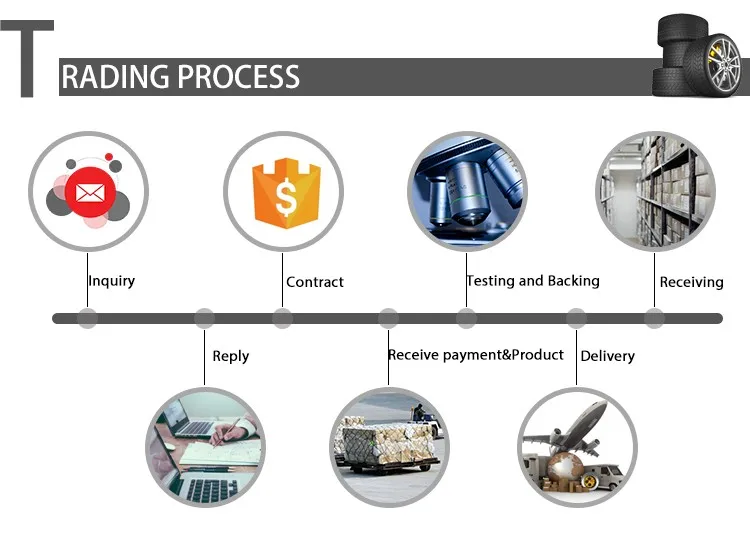

Transaction process

Certifications